Discussing Battery Trends in Electrification

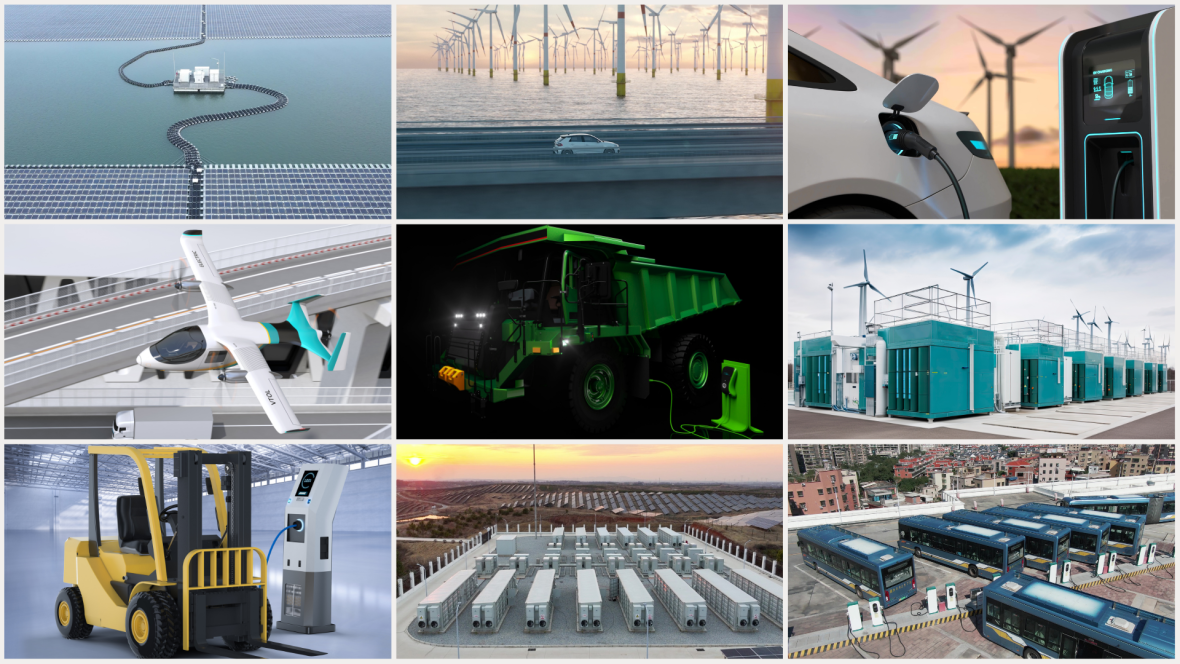

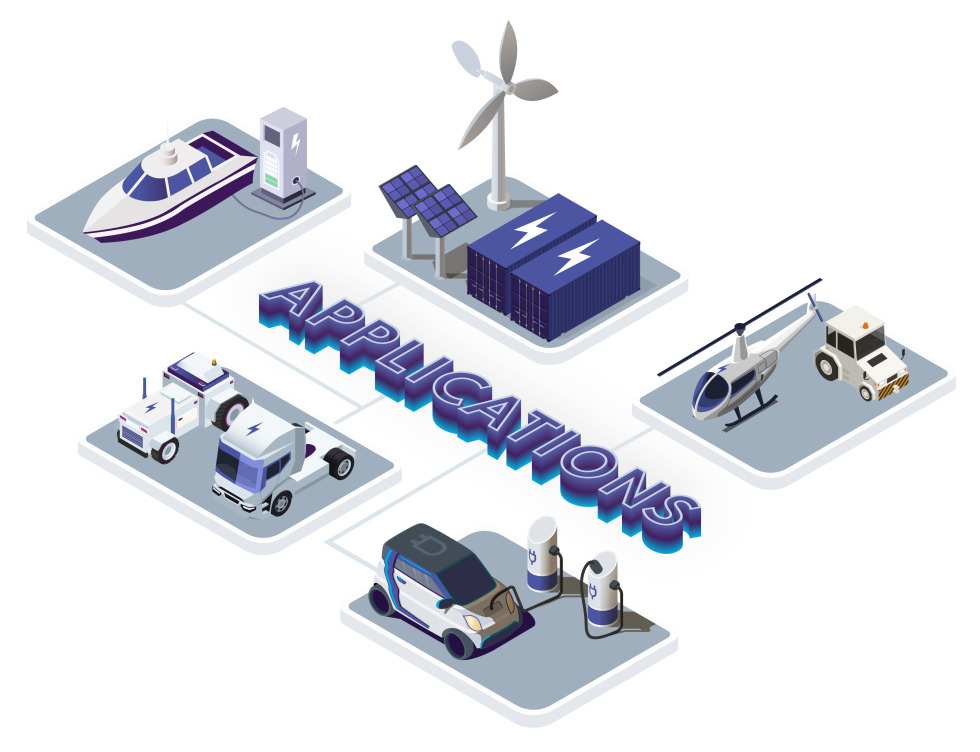

The battery landscape today is exceptionally diverse, driven by the specific needs of a wide variety of applications across automotive, industrial, and consumer markets1. From the compact cylindrical cells used in power tools and smaller vehicles like e-bikes, to larger prismatic and pouch cells found in consumer electric vehicles (EVs)2, industrial vehicles3, and stationary battery energy storage systems (BESS)4. Each application today has specific cell requirements, and yet there’s still many more to come that can benefit from electrification5.

A high-level view of battery trends

Broadly speaking, cylindrical cells are often used in batteries for their ease of manufacturing, cost, and mechanical robustness, while pouch cells can offer superior energy density for applications with strict weight and size constraints, and prismatic offer a blend of both with efficient use of space6.

However, an application not only impacts the preferred cell type but also the areas of performance that battery designers prioritize. Automotive batteries for consumer xEVs generally need to find a balance between range, safety, and cost, but some applications, such as the newer xEV variants that are appearing in agricultural and mining operations, will need to bias towards peak robustness due to the usage patterns and harsh environments they experience. Alternatively, BESS installations supporting renewable energy production will prioritize long life cycles, cost-efficiency, and ease of maintenance over compactness or weight.

New battery designs are also transforming the vehicle-cell dynamic. These include innovative architectures such as cell-to-pack (CTP), which removes the need for intermediate modules, and cell-to-chassis (CTC), which embeds cells directly into the vehicle’s core chassis for even further space and weight optimization. In both cases, the aim is to increase design flexibility, integration, energy density, and potentially simplify production7.

Examples of a prismatic cell (L), pouch cells (C), and cylindrical cells (R) fitted with Dukosi Cell Monitors

Major cell chemistries used today

Lithium-ion (Li-ion) remains the dominant chemistry due to its high energy density and relative longevity, making it suitable for a wide range of automotive and industrial applications. Li-ion is a broad name encompassing several different chemistries, such as nickel-manganese-cobalt (NMC) and lithium-iron-phosphate (LFP), the two most popular, that offer distinct trade-offs between capacity, performance and cost.

Cell type performance, safety, and cost advantages

NMC cells can offer higher energy density and performance, making them well suited for applications like passenger xEVs. However, they are more expensive and less stable than LFP cells. LFP offers slightly lower energy density and are more challenging to track State of Charge, but deliver improved safety and cost-effectiveness, making them ideal for more affordable xEVs, plus larger commercial or industrial vehicles applications like buses, as well as BESS.

Other emerging alternatives such as sodium-ion can offer unique advantages in cell safety and material availability, and ‘solid-state’ cells have long been seen as the ‘holy grail’ of performance, power density and longevity, but have so far faced challenges with cost and mass production viability.

The range of battery chemistries on the market reflects the scale and diversity of electrification required for global sustainability8. It also highlights the real need for flexible battery monitoring that can seamlessly adapt to the specific requirements of each chemistry, ensuring performance and safety are maintained across a wide range of applications.

Application influences in battery design

High-voltage, high-power batteries are central to electrification in both automotive and industrial settings, but their design and management do differ due to the unique requirements of each sector.

As mentioned before, automotive applications balance efficiency, safety, and range, necessitating batteries that can support long-distance travel and fast charging, with battery weight being a key consideration. To streamline production and manage costs, passenger xEVs require modular battery platforms capable of capacities ranging typically from around 40 kWh to 100 kWh. However, the ongoing trend of upgrading battery system voltage from 400V to 800V to enhance charging speeds and reduce energy losses is introducing new design complexities. In automotive battery management, safety is of utmost importance, but factors like streamlined integration and enhanced operation efficiency are also critical.

Larger industrial and commercial EV applications, however, must manage higher peak loads and more sustained operation, while frequently operating in challenging environments with high temperatures9 or continuous vibrations. Therefore, battery robustness and overall capacity are key10. This second element is especially crucial and affects the applications that can currently be addressed by industrial EVs.

For example, while the world’s biggest electric construction excavators weigh around 26 tons and use batteries of around 300 kWh, large mining vehicles can easily reach up to 1000 tons – far beyond the limits of today’s batteries. In order to meet the demands of vehicles working in harsh environments as well as larger vehicle types, the manufacturing of larger batteries needs to be simplified, while energy density and efficiency optimized.

In BESS applications, like those supporting renewable energy deployments, high-power batteries prioritize energy density, longevity, and thermal stability. Unlike automotive or industrial systems, BESS designs are less constrained by weight or size, enabling the use of larger-format prismatic cells, which can help to reduce design complexity and enhance durability. Nevertheless, challenges persist in guaranteeing the safety and maintainability of the system, mandating comprehensive sensing11 and battery monitoring to identify issues such as cell-level imbalances and to optimize energy distribution across battery packs for enhanced longevity and reliability12.

Despite their differences, all three markets will benefit from any technology that can enhance key performance metrics while improving production flexibility and scalability, especially as the total demand for high-voltage batteries continues to grow.

- https://www.dukosi.com/blog/what-industries-can-benefit-from-smarter-battery-solutions ↩︎

- https://www.dukosi.com/electric-vehicles ↩︎

- https://www.dukosi.com/industrial-transportation ↩︎

- https://www.dukosi.com/battery-energy-storage-systems ↩︎

- https://www.dukosi.com/blog/how-is-dukosi-leading-the-battery-trends-in-electrification ↩︎

- https://www.dukosi.com/blog/cylindrical-pouch-prismatic-flexible-battery-integration-options-with-dukosi-chip-on-cell-technology ↩︎

- https://www.dukosi.com/cell-manufacturing ↩︎

- https://www.dukosi.com/sustainability ↩︎

- https://www.dukosi.com/blog/monitoring-the-temperature-of-every-cell-to-maximize-safety-and-performance-of-high-power-batteries ↩︎

- https://www.dukosi.com/blog/promoting-the-safe-reliable-and-sustainable-electrification-of-industrial-transportation ↩︎

- https://www.dukosi.com/blog/importance-of-temperature-monitoring-to-improve-safety-and-reliability-of-battery-energy-storage-systems ↩︎

- https://www.dukosi.com/blog/sensitivity-of-lithium-ion-battery-soc-and-soh-estimates-to-sensor-measurement-error-and-latency ↩︎

All original content, graphics, images and media are copyright of Dukosi.