BMS Designers

Create more reliable, more cost-effective BMS for wide-ranging battery-powered applications.

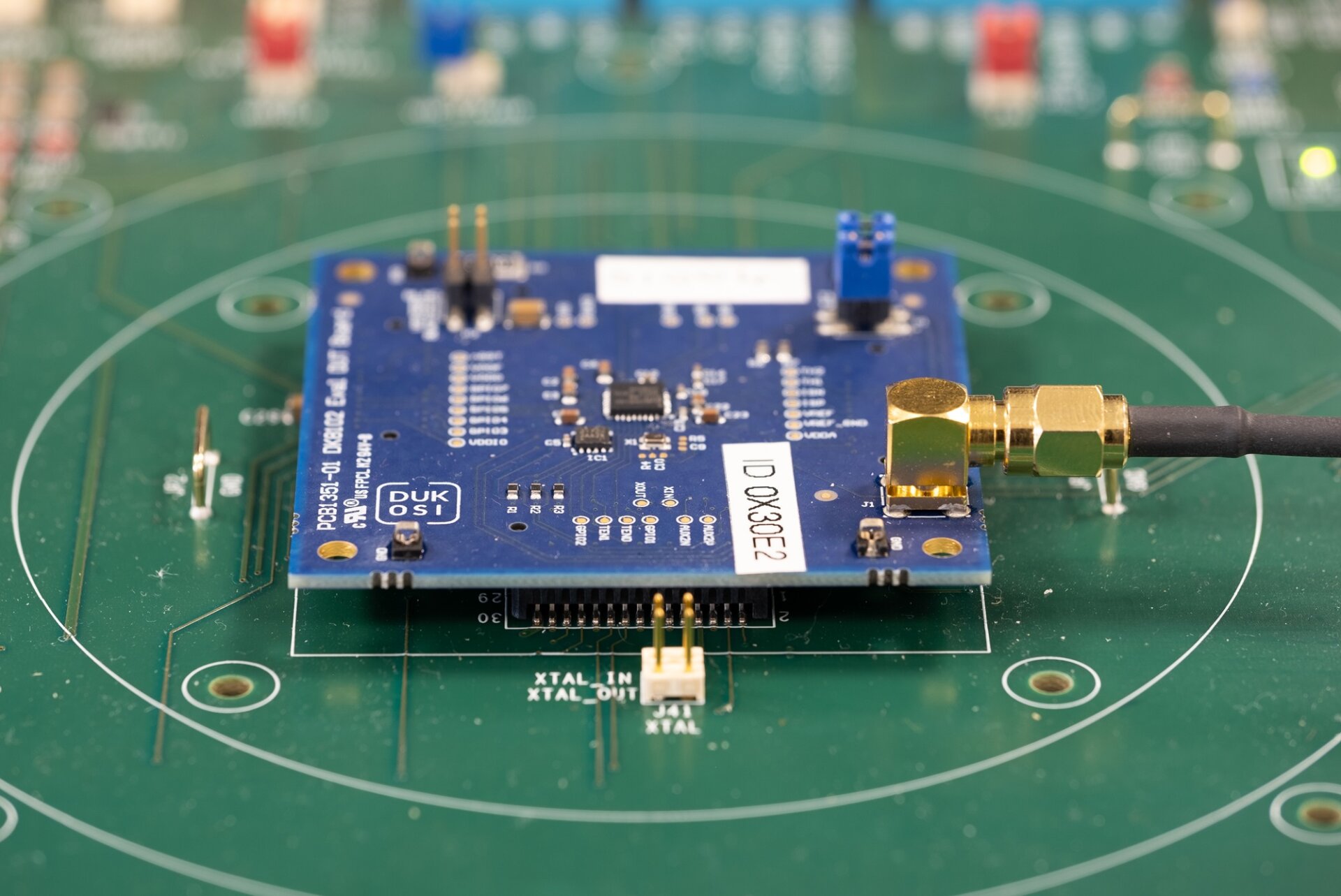

Supporting all BMS topologies. Simplify BMS design by using DKCMS™ with C-SynQ® communication, providing faster time to market, streamlined battery certification, and flexibility to accommodate different battery capacities.

Contactless, but without the drawbacks of wireless

Using a patented contactless communication system based on near field technology, the Dukosi Cell Monitoring Solution (DKCMS) offers all the reliability and cost benefits of removing the complex wiring harness, without the drawbacks of line of sight (LoS), interference mitigations, and security commitment of a far field wireless BMS system.

Cell-level data accuracy

With each Dukosi Cell Monitor recording highly accurate and detailed information of each cell’s behavior and lifetime status1, it provides new insights into a battery pack’s long-term use. This gives applications more confidence to unlock more performance from each cell while still achieving the same reliability and warranty standards.

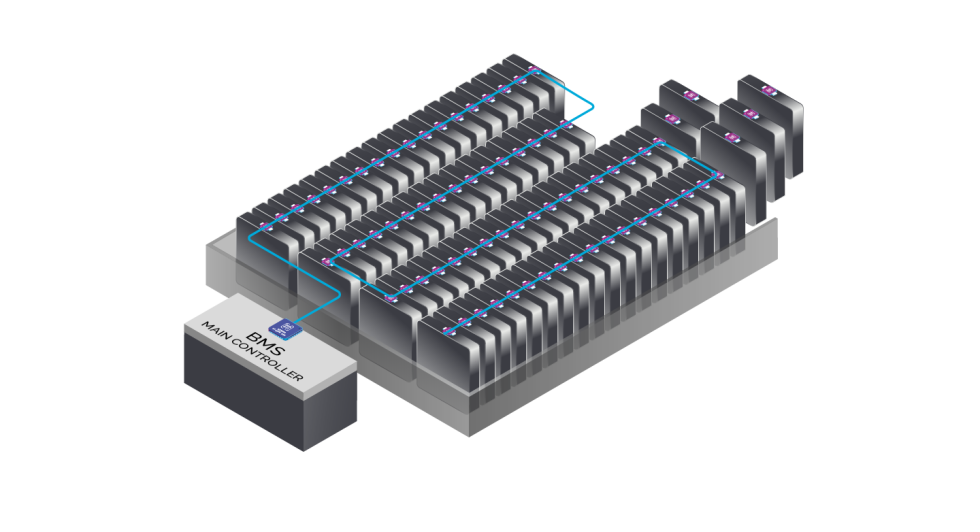

Flexible and scalable architecture

DKCMS allows application developers to scale easily and address different markets with varying battery capacities and chemistries, without making major BMS design changes. Simply add as many cells as needed to the pack and extend the bus antenna to facilitate communication to the Dukosi System Hub, and main BMS controller.

Enhance battery safety

DKCMS allows every cell in the battery pack to be monitored 24/7, even when the main BMS controller is in a low-power state. This provides immediate detection of cell-level problems and earlier fault diagnosis, creating safer, more reliable battery-powered applications. If necessary, the solution can wake the host controller at any time, even if the vehicle is unattended during shipping, storage, or periods between activity.

Reduce weight, improve reliability

Weight reductions and reliability improvements are achieved beyond the cell by eliminating the complex wiring harness, supplementary PCBs, connectors, module assemblies, and other associated components, creating a simpler, streamlined battery design.

1.In development

Working with Dukosi

At Dukosi, we are driven by our mission to bring revolutionary changes to battery-powered applications. To achieve this, we put active collaboration into practice at technical, operational and strategic levels with our customers and partners. Our partners have been selected based on shared commitment to innovation and excellence, and their ability to deliver strong and trustworthy solutions that help accelerate customers’ development efforts and expedite time to market.