Cylindrical, Pouch, Prismatic? Flexible Battery Integration Options with Dukosi Chip-on-cell Technology

Please note: This article has been superseded with an updated blog titled “Accelerate Next-Generation Battery Designs with DKCMS™”, which highlights our latest integrations and technologies.1

Whether designing a new battery using cylindrical, pouch, or prismatic cells, Dukosi Cell Monitors2 can be applied to every cell, parallel cell group, or even to traditional cell modules, simplifying the architecture and reducing design, validation, and manufacturing costs.

Learn more about the core components of the Dukosi Cell Monitoring System (DKCMS™)3 and the advantages it offers to wide-ranging applications4, such as electric vehicles (xEV)5, industrial transportation6, and stationary battery energy storage systems (BESS)7.

Here are some integration examples:

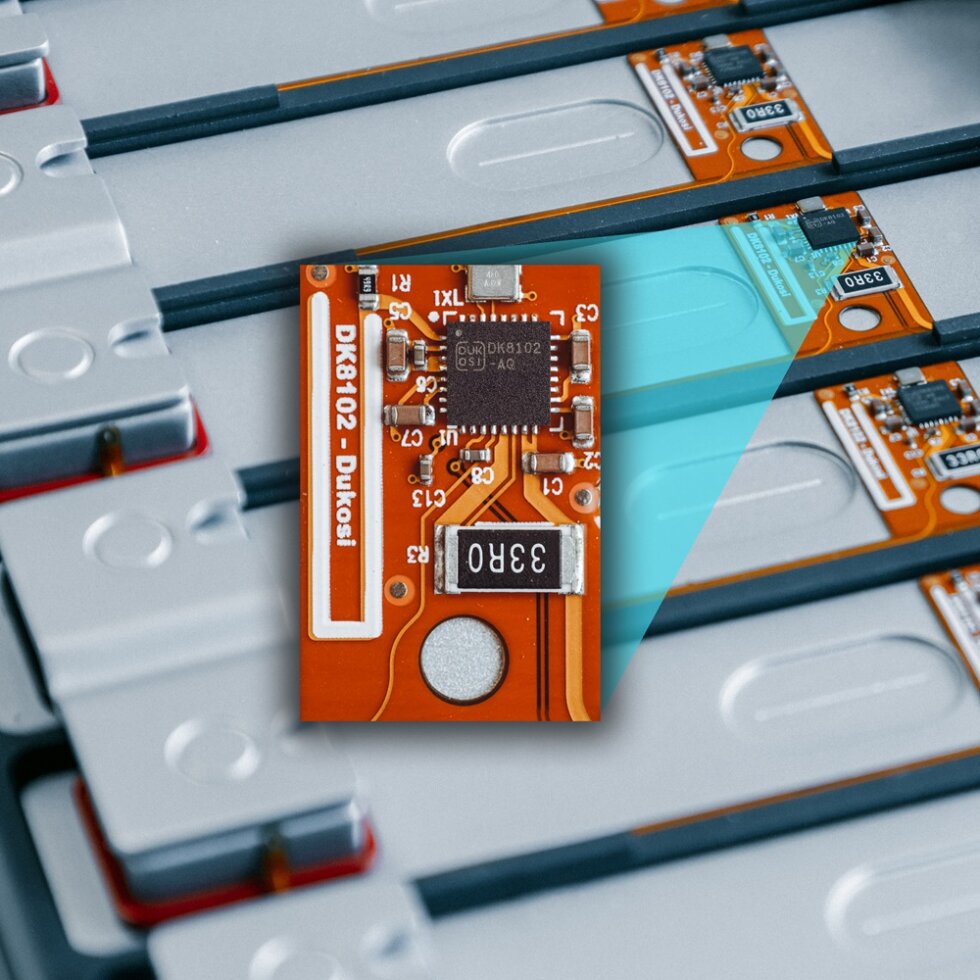

Prismatic cells

Prismatic cells are growing in popularity because of their high energy density, space utilization, durability, thermal management, and inherent package strength, enabling new battery designs such as cell to pack (CTP), or even more advanced designs like cell to body (CTB) or cell to chassis (CTC).

By placing the Dukosi cell monitor on a highly compact flexible or rigid PCB between the terminals, the chip can readily assess the skin temperature of the cell.

Up to two additional thermistors can be placed along other edges for greater thermal insight into how the cell is performing. This can be done for research and development purposes or if maximizing safety is a critical design factor, such as in aerospace8 or marine9 applications.

Prismatic cells with Dukosi Cell Monitors installed

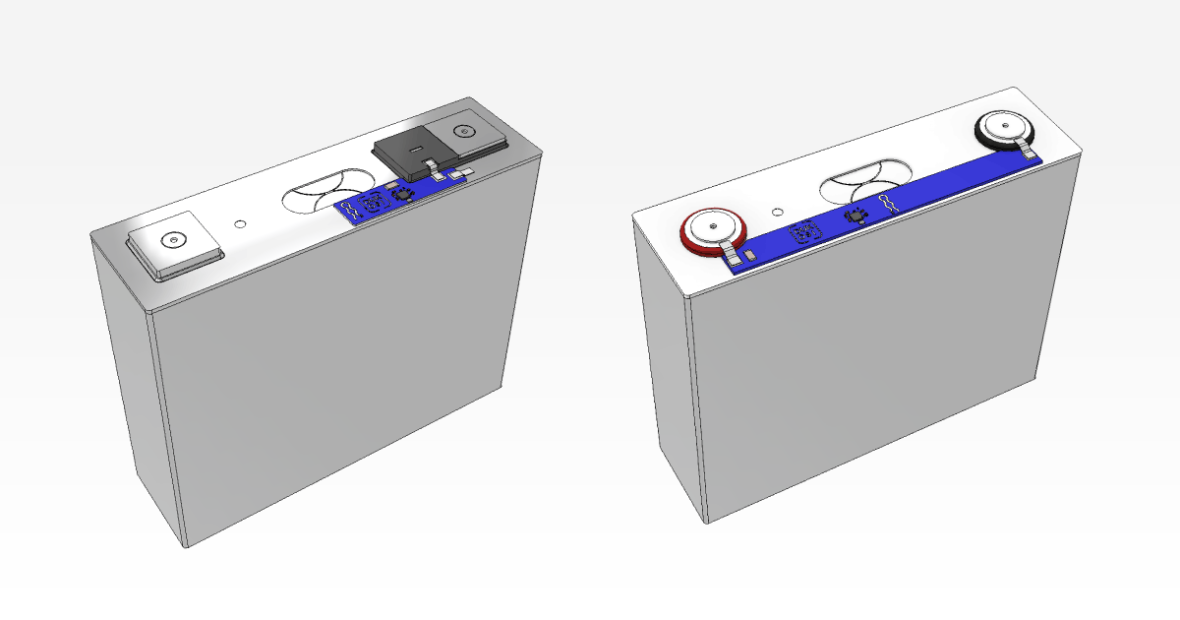

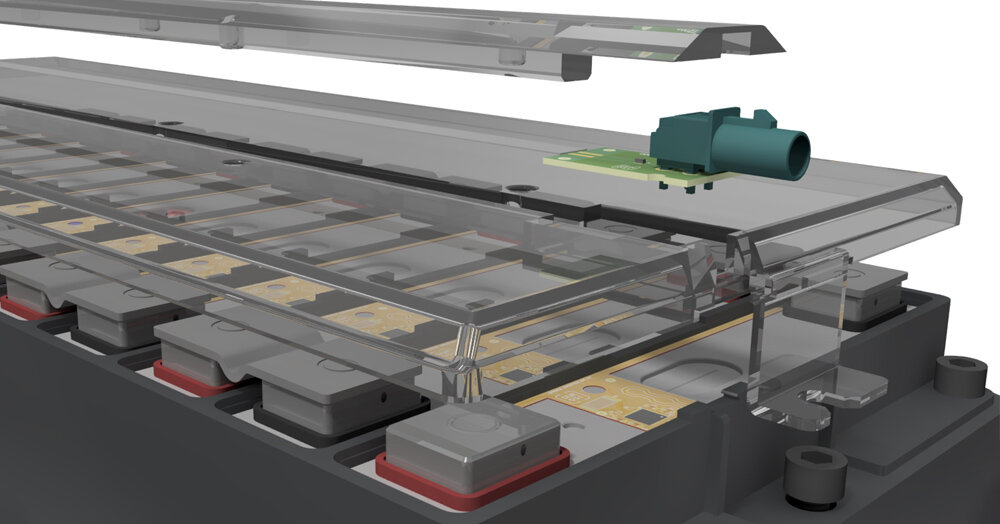

With the cells stacked together and cell monitors aligned, the contactless bus antenna can be easily routed near each Cell Monitor, potentially even integrating it into the battery lid, as shown below.

A battery module enclosure with lid-integrated near field antenna, created in collaboration with Forward Engineering 10

For battery designs based on cell modules, Dukosi Cell Monitors can be installed in lieu of the traditional multi-cell monitor PCBA. This continues to provide many advantages in reliability and ease of installation of the bus antenna, which can be mounted into the lid or housing.

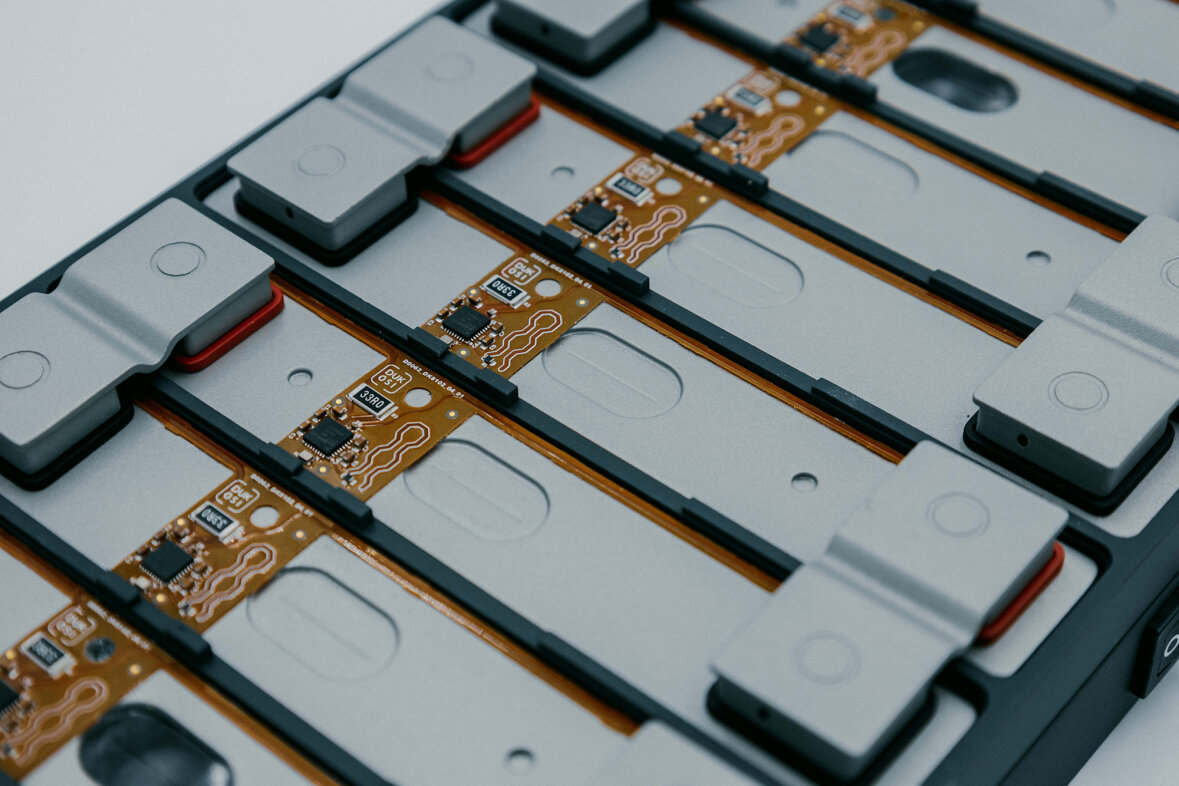

Pouch cells

Pouch cells offer high energy density with lightweight construction. They are a cost-effective solution with a compact shape for efficient use of space. They can be used directly or packaged in plastic cassettes (shown below) to improve durability and installation benefits.

The Dukosi Cell Monitor can be placed on a highly compact, flexible PCB directly on the cell next to one of the terminals, with another flexi-PCB connecting to the other terminal.

Pouch cell integration example with Dukosi Cell Monitors installed

Additional thermistors can potentially be integrated into the same PCB line to sample additional temperature points along the length of the cell.

This is ideal for accurate thermal tracking due to the slimness of the laminated film packaging, which reduces the distance between the internal cell chemistry and the external thermistor(s).

Various antenna options – standard or orthogonal – are available, providing a contactless link from each Cell Monitor to the bus antenna.

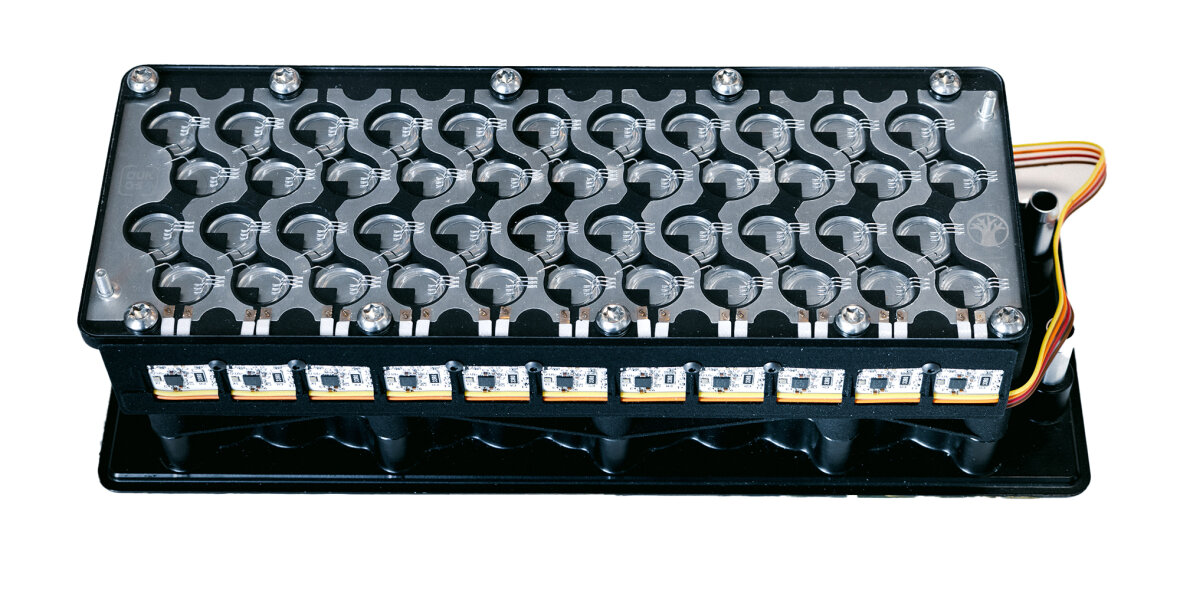

Cylindrical cells

Cylindrical cells remain popular due to their well-established manufacturing efficiency and yield, mechanical robustness, and thermal management11. These cells offer a large, even surface area relative to their volume for effective heat dissipation.

Due to their shape and size, cylindrical cells are typically grouped in parallel strings, with one Cell Monitor per string. The Dukosi solution offers benefits such as simplifying the battery architecture and communication with the BMS host12, and it has the ability to measure both the core and edge temperatures of the group of parallel cells. Our integration example shows each Cell Monitor connecting to a series of cells via a flexible PCB attached to busbars, with the wireless antenna routed along one edge of the module for ease of manufacturing.

Get ahead in the industry by contacting Dukosi13 to see how we can help you create your next cutting-edge battery design.

- https://www.dukosi.com/blog/accelerate-next-generation-battery-designs-with-dkcms ↩︎

- https://www.dukosi.com/dkcms-core ↩︎

- https://www.dukosi.com/dukosi-cell-monitoring-system-dkcms ↩︎

- https://www.dukosi.com/blog/what-industries-can-benefit-from-smarter-battery-solutions ↩︎

- https://www.dukosi.com/electric-vehicles ↩︎

- https://www.dukosi.com/industrial-transportation ↩︎

- https://www.dukosi.com/battery-energy-storage-systems ↩︎

- https://www.dukosi.com/blog/maximizing-safety-and-reliability-in-batteries-for-evtol-aircraft ↩︎

- https://www.dukosi.com/blog/safe-electrification-of-shipping-and-battery-storage-in-marine-applications ↩︎

- https://www.dukosi.com/blog/case-study-an-optimized-battery-enclosure-design-with-dkcms-communication-integration ↩︎

- https://www.dukosi.com/blog/case-study-importance-of-per-cell-temperature-monitoring-to-maximize-safety ↩︎

- https://www.dukosi.com/bms-designers ↩︎

- https://www.dukosi.com/contact-us ↩︎

All original content, graphics, images and media are copyright of Dukosi.