Cell Manufacturing

Build supply chain trust, security and safety for customers

Manufacture and ship cells with supply chain trust and security built-in. Give customers cell-level lifetime data1 and condition monitoring from the moment of manufacture.

Maximize supply chain trust and security

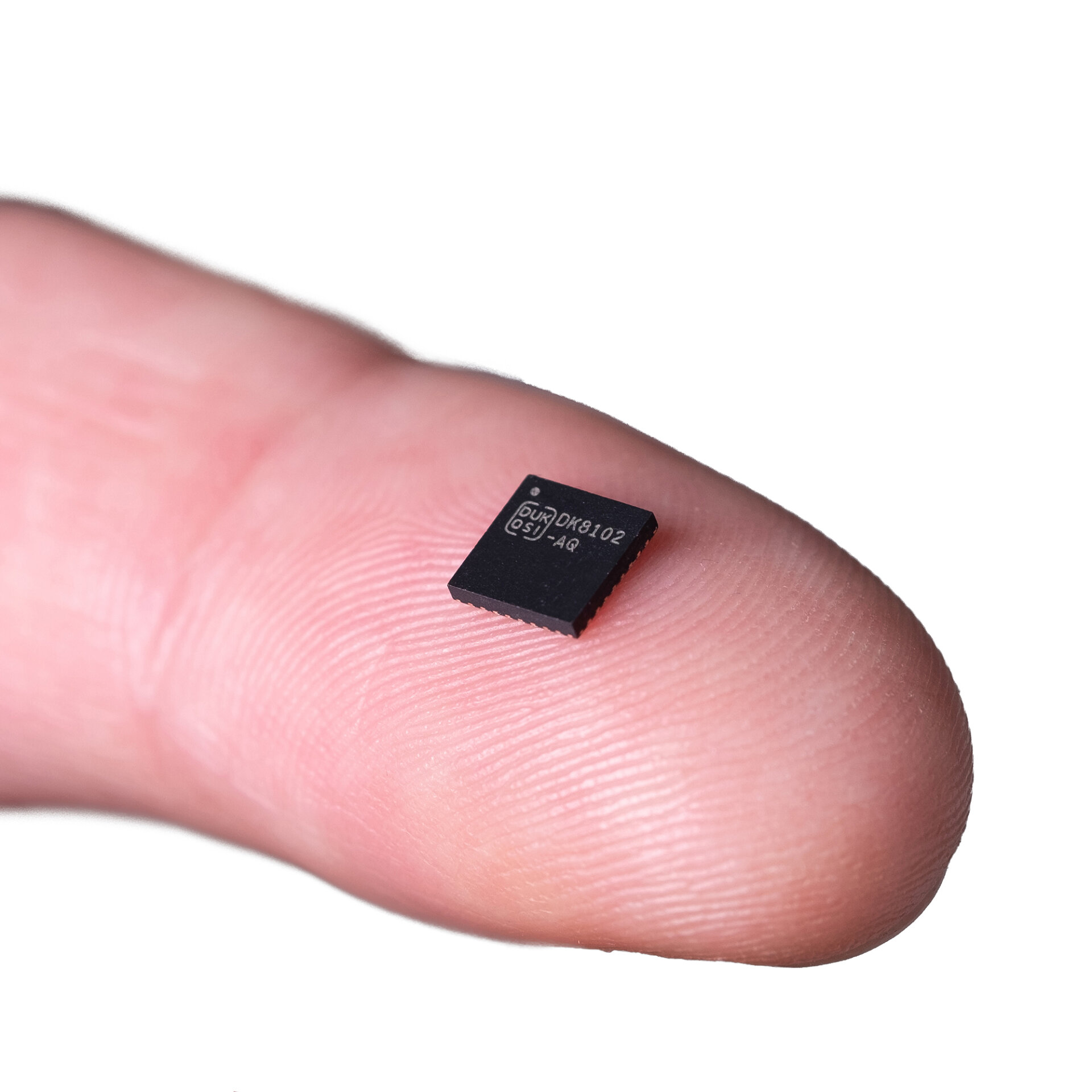

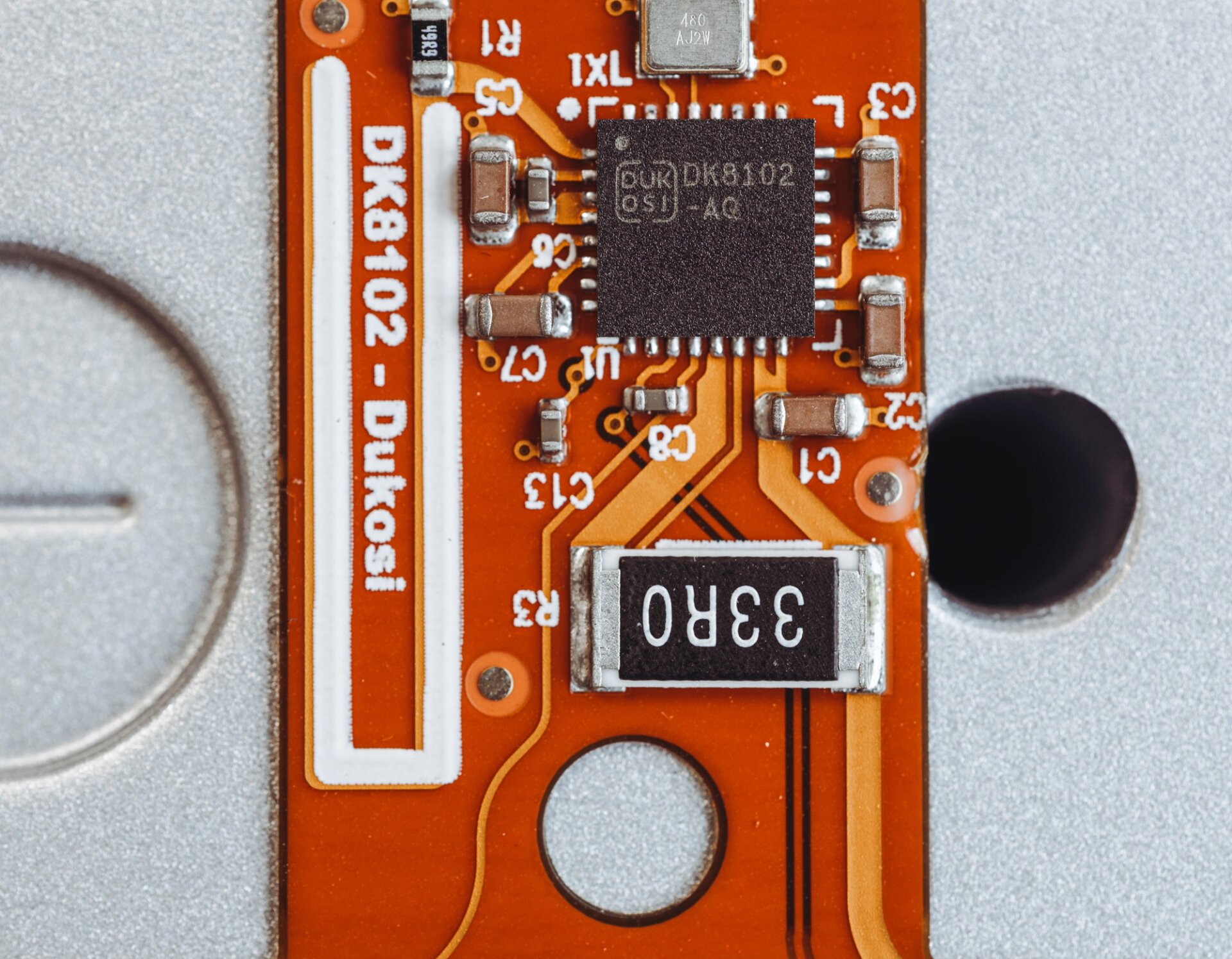

By using Dukosi Cell Monitoring Solution (DKCMS™) during cell manufacture, the data stored within the Cell Monitor IC ensures both are ‘tied together’, i.e. recording each cell serial number in its secure data store, which provides a layer of trust as the stored information must reflect the cell it’s attached to.

Cell-specific information stored includes manufacturer, raw material sources, date and time, and serial number, as well as dynamic parameters like temperature and voltage, which are constantly monitored and logged on each cell from day 11.

Integrating the Dukosi Cell Monitor during back-end formation ensures that the lifetime data can never be removed without damaging the cell beyond use, offering a 100% secure solution.

Quickly optimize manufacturing scale-up with 24/7 cell monitoring

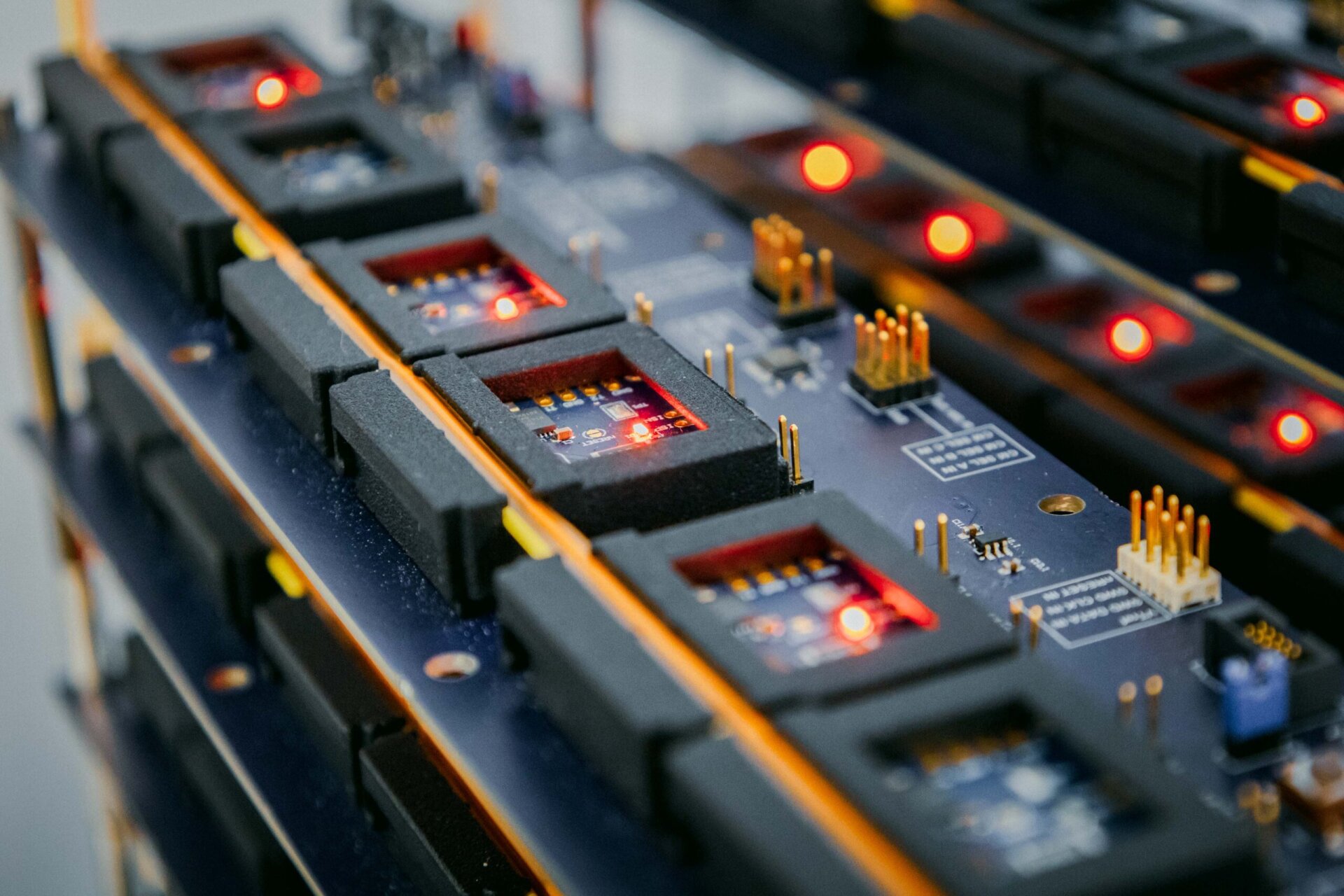

By implementing DKCMS during cell manufacturing, the Cell Monitor starts logging data immediately, providing continuous 24/7 monitoring1. Reading the Cell Monitor during the manufacturing process and quality assurance testing can simplify operations, improving efficiency.

Unlock insights into cell use and ageing

Through cell-level insights, cell makers can, for the first time, begin to collect a more detailed picture of each cell’s lifecycle. By collecting data on every cell produced, it can offer deep analytics that become the basis of intelligent decisions to optimize their products for future generations of batteries.

Enhanced safety with real-time monitoring

DKCMS enables safer batteries during manufacturing, storage and shipping. When the manufacturing line or storage area is equipped with a Dukosi System Hub to read the data from each Cell Monitor, proactive measures can be taken to identify and remove faulty cells. It’s particularly useful during the safety-critical cell ageing phase of manufacturing, where the cells are tested over a longer period for the first time.

Lower liability and warranty risk with accurate data and event logging

24/7 cell monitoring includes continuous logging during inactive times such as storage or shipping, ensuring full lifetime data collection. Event logging1 helps to manage warranty claims efficiently, avoiding potential conflicts. It greatly reduces the safety measures required during shipping, while testing time post-transport is greatly accelerated, which reduces operating costs. Should something go wrong, it is quick to ascertain if the issue arose at the cell manufacturer, during shipping or after arriving at their customer, assigning liability efficiently.

1.In development

Working with Dukosi

At Dukosi, we are driven by our mission to bring revolutionary changes to battery-powered applications. To achieve this, we put active collaboration into practice at technical, operational and strategic levels with our customers and partners. Our partners have been selected based on shared commitment to innovation and excellence, and their ability to deliver strong and trustworthy solutions that help accelerate customers’ development efforts and expedite time to market.