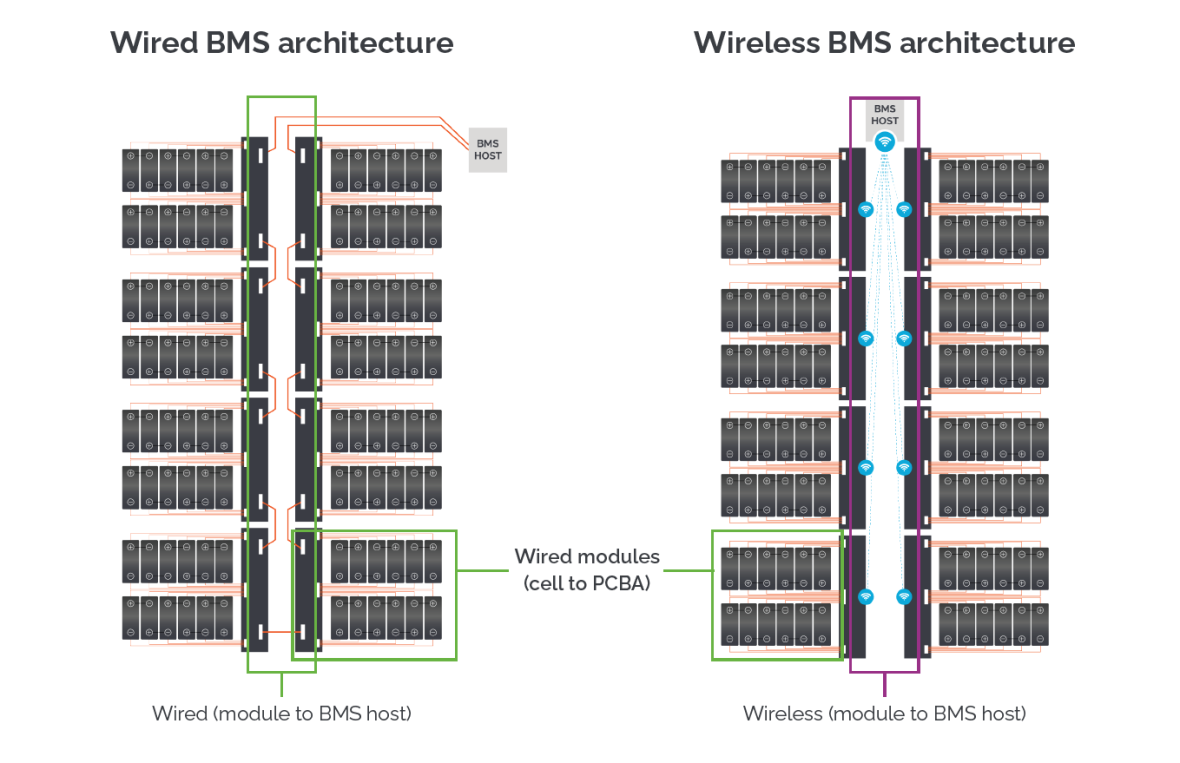

Comparing Wired, Wireless and Contactless BMS Architectures

Battery energy storage systems (BESS)1 and electric vehicles (xEV)2 are crucial technologies required to achieve a sustainable future, and demand for these is predicted to keep growing. To meet their diverse market needs, battery production must be sustainable, scalable and flexible. However, current designs are complex and present several technical challenges and limitations:

Scaling wired designs can be difficult:

- Adding or removing modules requires a complete redesign of the battery pack.

- The complexity of the wiring is technically challenging, and labor intensive, increasing assembly cost and time.

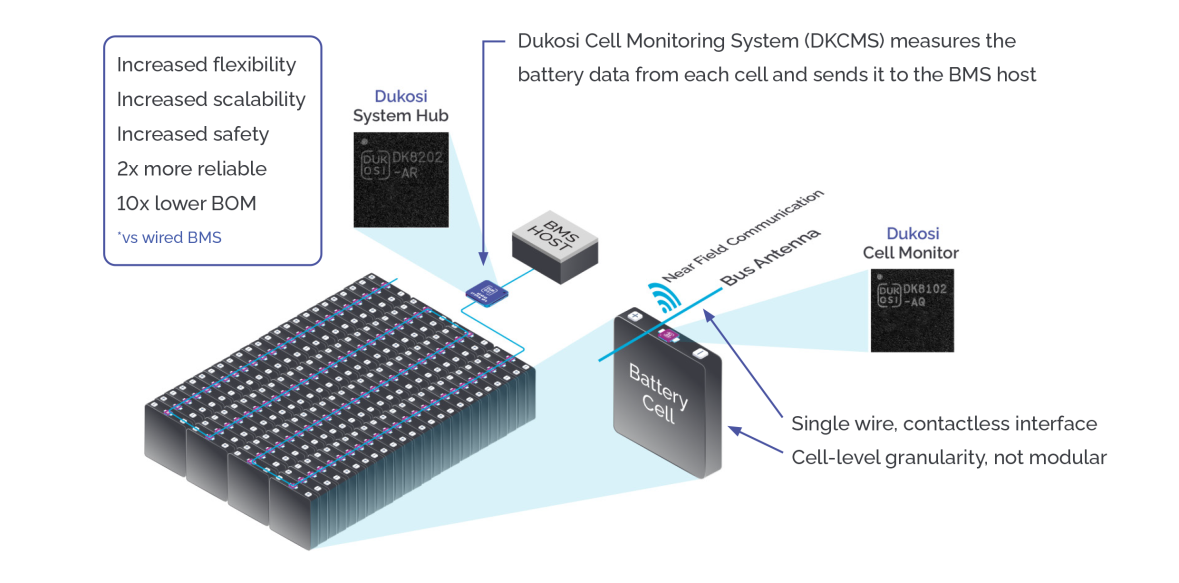

Dukosi’s contactless battery architecture

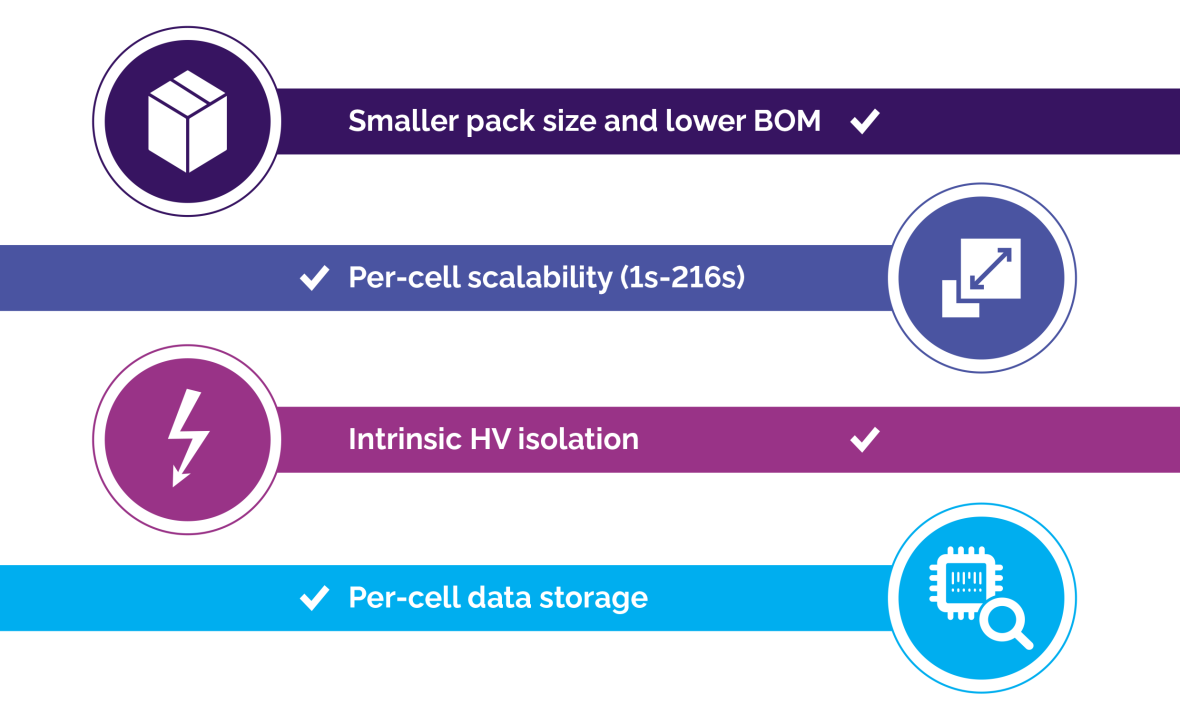

By eliminating the complex wiring harness and connectors from the battery pack, Dukosi’s solution simplifies manufacturing, improves safety, reduces costs and increases reliability, ultimately enabling greater scalability to meet the rapidly growing demand for high-powered battery applications3.

Dukosi Cell Monitoring System (DKCMS™) advantages

Beyond the battery

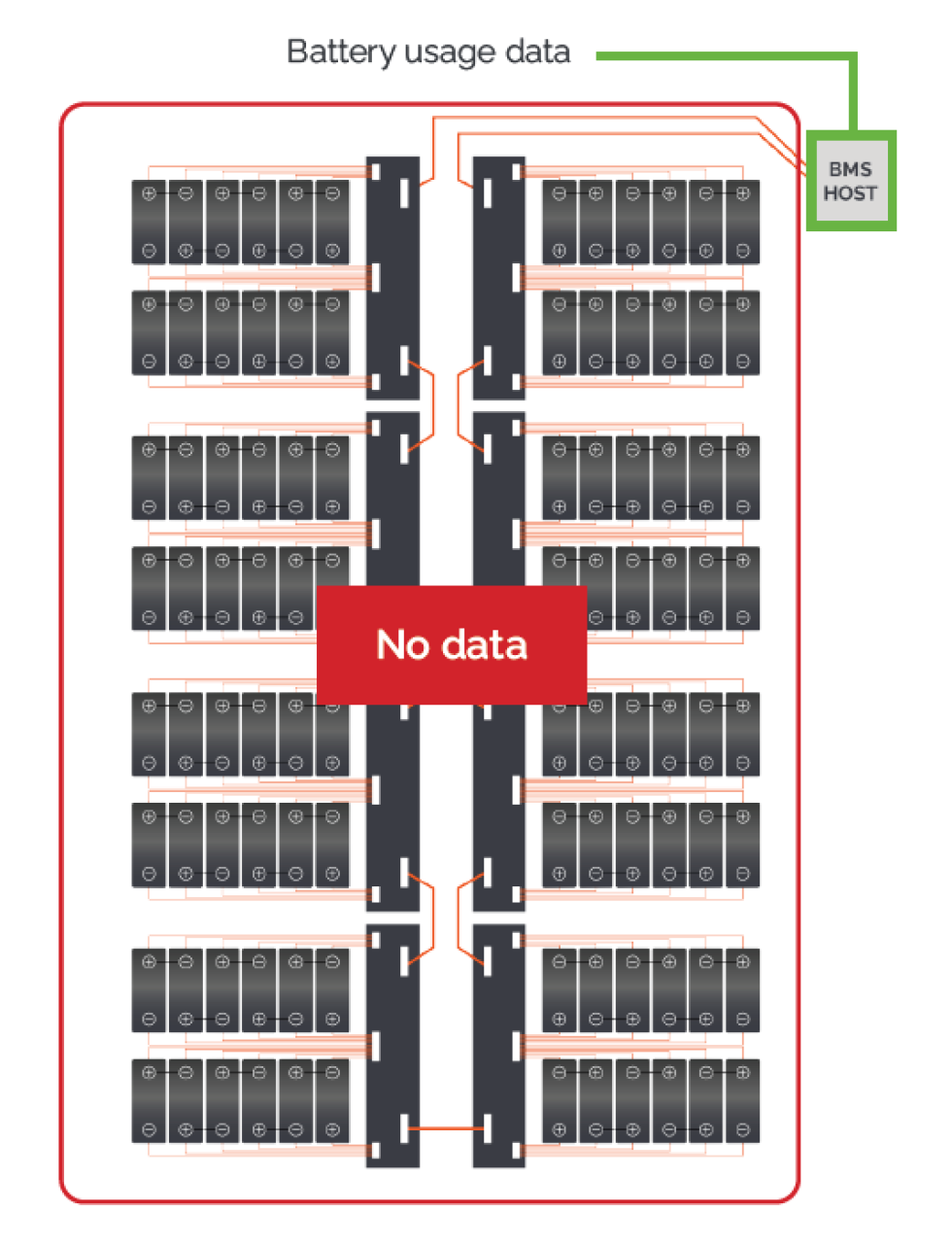

Enabling a circular economy at the cell level

In other architectures, battery usage and provenance data are recorded in the BMS host. The usage data is stored, providing the cells remain in the battery4. Insight into each cell’s life before or after integration with the BMS is not recorded, limiting reuse and recycling opportunities.

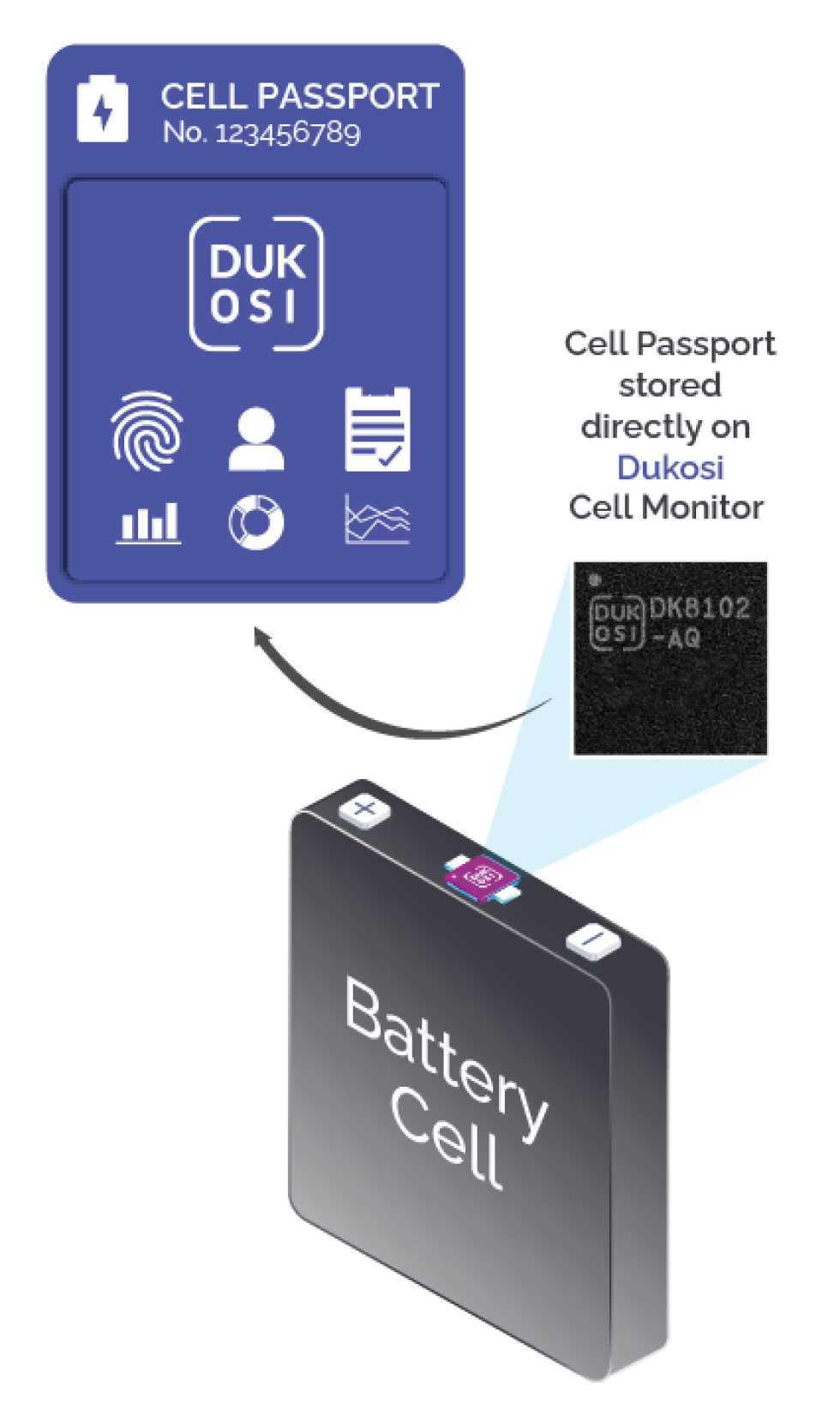

Dukosi’s solution captures and stores the lifetime data of each cell on each Cell Monitor for the life of the cell, enabling a circular economy (reduce, reuse, recycle) and sustainable battery value chain5.

- Supports battery passport

- Lifetime usage data

- Provenance information

- Materials information

- Supplier details

- Unique identifiers and custom fields

Learn more about the differences between wired, wireless and contactless battery management systems in our white paper6.

Contact us7 to learn about how Dukosi can help you meet your battery system design, performance, safety and/or sustainability goals.

- https://www.dukosi.com/battery-energy-storage-systems ↩︎

- https://www.dukosi.com/electric-vehicles ↩︎

- https://www.dukosi.com/blog/what-industries-can-benefit-from-smarter-battery-solutions ↩︎

- https://www.press-eu.kia.com/document/633#/latest-news/kia-becomes-first-oem-to-publicly-trial-cell-level-battery-passport-technology-1 ↩︎

- https://www.dukosi.com/sustainability ↩︎

- https://www.dukosi.com/blog/white-paper-wired-wireless-and-contactless-comparing-bms-design-approaches ↩︎

- https://www.dukosi.com/contact-us ↩︎

All original content, graphics, images and media are copyright of Dukosi.