The Humble Cell Paves the Road to an EV Battery Circular Economy

With the move to greater electrification and proliferation of electric vehicles (xEVs), the need to build a circular economy for batteries and their cells has become an economic, social, and environmental imperative. Eventually, all batteries reach their end of life, and we need to promote recovery, reuse, and recycling to ensure a sustainable future. As second-life applications become more integral to building a sustainable battery supply chain, understanding their provenance and how they’ve been used and stored is critical to ensuring it.

This is where the humble cell, the smallest unit of the battery system, takes on a leading role in the sustainability story. For example, instead of scrapping an xEV battery1, it could find a second life in a stationary energy storage solution; however, that can present a daunting task of accurately assessing and grading every cell within the battery. Fortunately, advanced cell monitoring technologies are now at hand to relieve this expense and burden, and make battery state of health information2 instantly available to users.

There are challenges moving towards a more sustainable battery value chain because, beyond the voltage readout, the status of each cell inside a typical battery is unknown once it is removed from the primary application. Without knowing this, the whole battery must be treated as a hazardous substance as a matter of safety. This increases the cost of recycling because in order to recover and reuse cells they must be carefully transported and processed, assuming every cell is dangerous. For example, the cost of shipping lithium-ion cells can be up to 10 times greater when the status and history of the cell are unknown because the highest amount of safety measures and insurance must be applied.

We must, therefore, improve the efficiency of the entire value chain, make battery and cell handling safer, and streamline the ease with which batteries and their cells can be reused in order to achieve our sustainability objectives.

New regulations based on the European Green Deal3 – the ‘Battery Passport’4 – are a step towards enabling a circular economy by giving batteries an element of traceability through the entire supply chain and lifecycle. However, today’s regulation is based on battery-level data. Future requirements will go beyond this, as full traceability can only be achieved at the cell level, the smallest unit of the battery system.

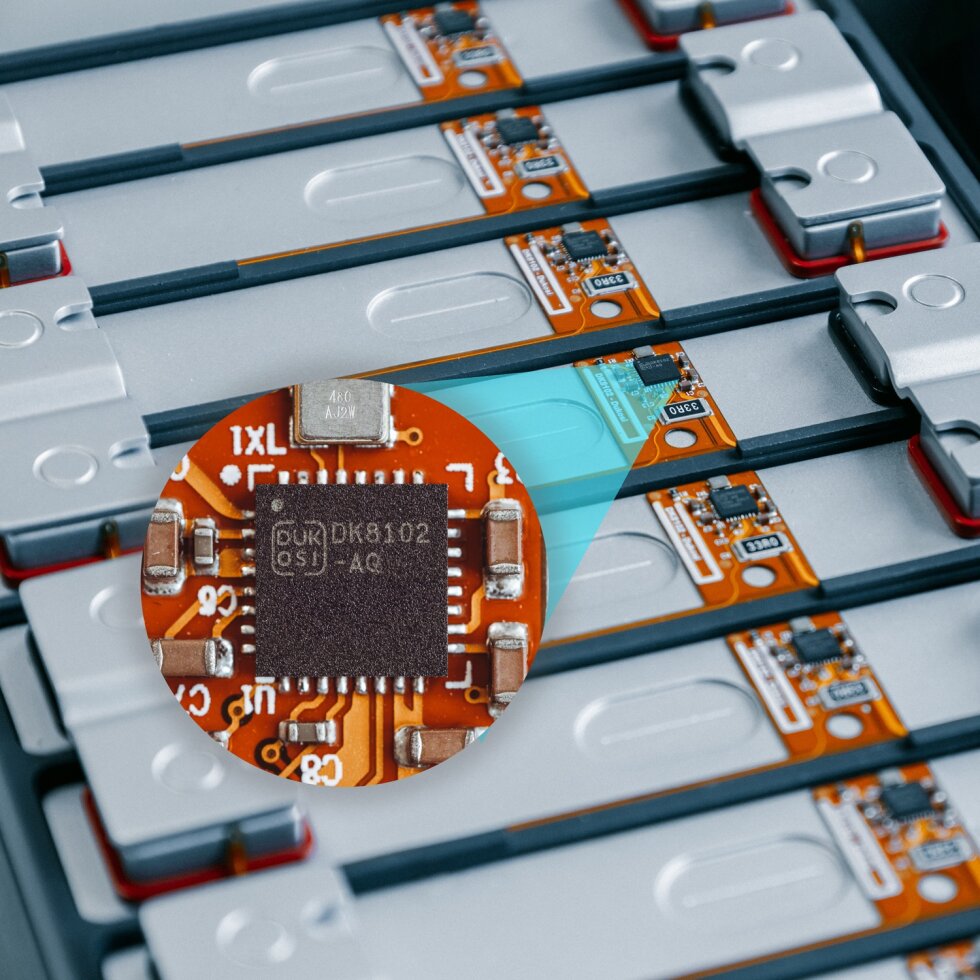

Enter Dukosi’s unique cell-level monitoring solution: the Dukosi Cell Monitoring System (DKCMS™)5. This intelligent chip-on-cell technology stores provenance, lifetime data and event logging on each cell, enabling full traceability throughout the cell’s lifecycle. From the moment the chip is added to the cell, data logging automatically begins, storing answers to a plethora of questions needed to determine state of health and safety; How has it been used? Has it ever been subjected to extremes of temperature during shipping or when in use? Has it been used before today? When and where was it precisely manufactured? How many cycles has this cell been subjected to? Does it match the other cells in the battery? Dukosi’s chip-on-cell technology stores all this and more and is available at any stage in the cell’s lifecycle. This traceability and local permanent storage remove the possibility of the cell’s history being lost and removes barriers like private cloud systems because the data always remains at the edge, with the cell itself.

It is this level of insight into each cell’s history that will allow us to maximize the productivity and safety of batteries in first and second life use, help support recovery of battery materials, and build a circular battery value chain for a more sustainable future.

At Dukosi we are laser-focused on enabling a truly circular economy by helping our customers optimize how batteries are used today in their main application and, in addition, by adding a second and third life to each and every battery, making the entire lifecycle more sustainable6.

- https://www.dukosi.com/electric-vehicles ↩︎

- https://www.dukosi.com/blog/battery-state-of-health-soh-the-powerhouse-behind-the-battery-passport ↩︎

- https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en ↩︎

- https://thebatterypass.eu/ ↩︎

- https://www.dukosi.com/dukosi-cell-monitoring-system-dkcms ↩︎

- https://www.dukosi.com/sustainability ↩︎

All original content, graphics, images and media are copyright of Dukosi.