Immersion Cooling of Lithium-ion Batteries

The Need for Advanced Thermal Management

As lithium-ion cell performance continues to improve, so do expectations for safety, reliability, and lifecycle. Effective temperature management of battery cells is fundamental to achieving these goals. Conventional liquid cooling techniques typically rely on cold plates or interface materials in contact with only one side of the cell, limiting the thermal transfer area and leaving potential for hotspots.

Immersion Cooling: A Full-Contact Approach

Immersion cooling offers an alternative. By directly submerging cells in a dielectric (non-conductive) fluid it achieves uniform thermal transfer across the full surface of each cell. Circulating the fluid through the housing ensures continuous flow, preventing localized overheating and delivering higher-efficiency cooling performance. Certain dielectric fluids have achieved heat transfer rates up to 10,000 times greater than air1. in controlled environments. This enables highly uniform temperature distribution, minimizing hotspots and reducing thermal stress.

A full immersed DKCMS undergoing in-house lab testing

Timing and Market Drivers

During the early stages of electric vehicle (EV) adoption, when pack designs were evolving and production volumes were low, manufacturers avoided introducing unproven cooling methods. Today, with maturing architectures, expanding fast-charging infrastructure, and rising consumer expectations, the thermal demands on EV battery systems are intensifying. Immersion cooling has therefore shifted from a conceptual innovation to a timely solution.

In battery energy storage system (BESS) applications, immersion cooling offers enhanced safety, improved longevity, and better performance under critical conditions. It can also help reduce system complexity by serving as part of the fire suppression system.

In parallel, many in the industry view immersion cooling as the ultimate solution for thermal management in the latest generation of data centers2, which are often supported by BESS. These data centers demand immense amounts of power, with each rack capable of generating more than 100 kW of heat3. The combination of high-power electronics in a dielectric coolant presents a clear industry parallel, and the insights gained here can help accelerate adoption in the broader battery industry.

Technical Advantages

Immersion cooling offers several advantages including faster cell pre-conditioning, sustained ultra-fast charging, and high-power operation. In addition, there are system integration benefits; by eliminating complex thermal hardware and enabling more compact, lightweight designs. This improves overall pack energy density (kWh/kg and kWh/l) and simplifies system architecture.

Evidence from laboratory and field trials continues to strengthen the case. In a collaborative project, Ricardo4 and TotalEnergies5 demonstrated up to 40% faster peak charging rates, 48% higher power density, and measurable improvements in battery life. These findings support immersion cooling as a pathway to higher performance and improved durability in electric vehicle (EV) battery systems.

Implementation Challenges

Despite its advantages, adoption has been limited by manufacturing and system-level hurdles. Conventional wired battery management systems (BMS) require long sensor leads to connect each cell to the controller, plus additional thermistors, and current sensor. In immersion environments, sealing these wires is technically challenging and cost-intensive, reducing practicality at scale.

A wired battery module with an immersion cooling setup requires the many sense wires to be sealed, which is extremely difficult and costly to achieve, limiting its use.

The Role of Dukosi’s DKCMS™ in Enabling Immersion-Cooled Batteries

To address the challenges and unlock the potential of immersion cooling, battery manufacturers need to consider a simpler architecture, but without compromising on essential safety, reliability, and ease of use. Dukosi’s Cell Monitoring System (DKCMS™)6 directly addresses these issues, offering a novel contactless architecture that is inherently well-suited for immersion-cooled designs.

Contactless Monitoring and Communication

Conventional packs rely on extensive wiring to connect each cell, thermistors, and sensors to module controllers. In immersion systems, sealing and routing these harnesses is technically difficult and costly; DKCMS eliminates this dependency by using a single wire interface.

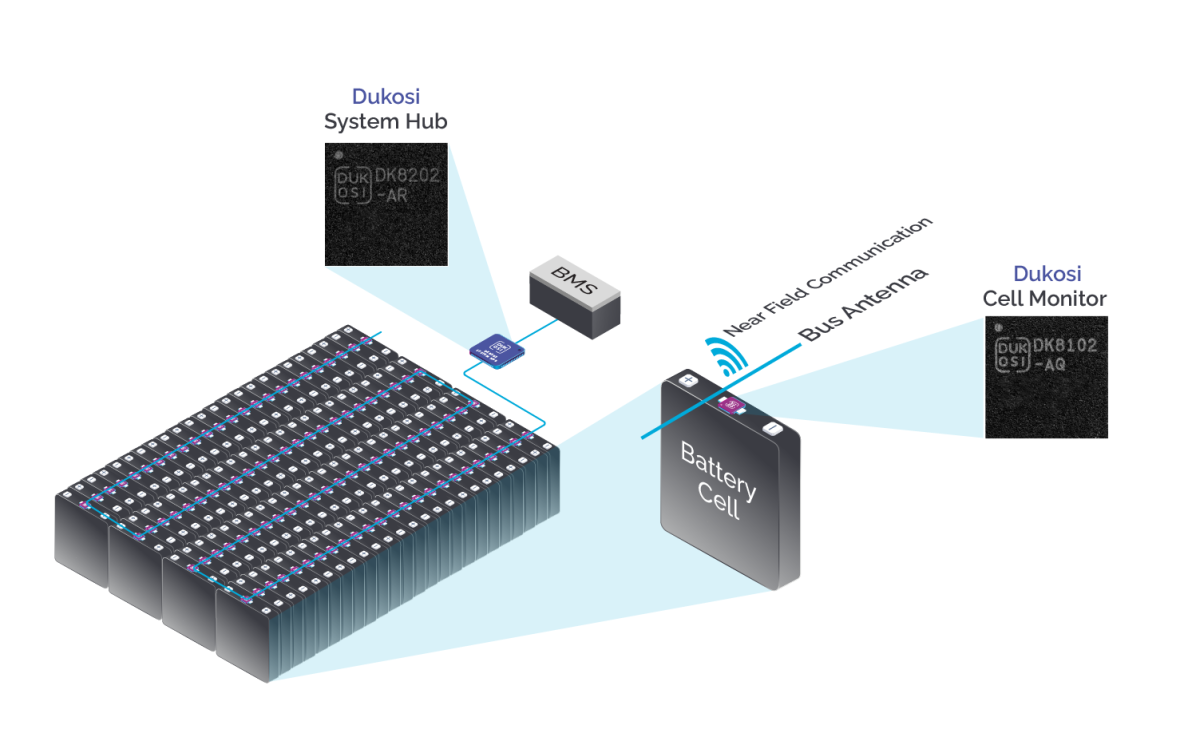

Each DK8102 Cell Monitor is installed directly on the cell, measuring voltage and up to three temperature points. Up to 216 Cell Monitors are networked using contactless near field connectivity via a single bus antenna wire to the DK8202 System Hub, which aggregates data for the vehicle’s BMS. Communication is enabled through C-SynQ®7, Dukosi’s proprietary protocol designed specifically for high-performance battery packs. The architecture delivers high-fidelity, synchronous data capture with full galvanic isolation — all without sense wires, thermistor harnesses, or module control boards.

A DKCMS-based contactless battery immersion cooling system configuration opportunities, including the communications antenna housed within the liquid (top), or built into the module casing, outside the liquid (bottom).

Benefits for Immersion-Cooled Designs

This shift from wired to contactless design can reduce component count by up to 10× compared to conventional packs. Fewer components simplify integration, improve reliability by up to 2x, and allow more freedom for coolant flow within immersion systems. Dukosi has validated DKCMS operation in dielectric fluids, confirming reliable communication performance with no degradation. This compatibility further strengthens its role as a foundation technology for immersion-cooled batteries.

The battery architecture of Dukosi Cell Monitoring System (DKCMS)

Pathway to Adoption

Customers are already independently developing immersion-cooled battery designs using DKCMS in their battery energy storage applications. These activities demonstrate commercial feasibility, and point toward automotive adoption where enhanced thermal management, improved pack safety, and simplified manufacturing are critical.

Conclusion

As EVs evolve, their battery systems must advance on all technology fronts – cells, architecture, thermal management, safety, reliability, integration. DKCMS not only improves monitoring accuracy and system efficiency, but also unlocks design freedoms that make immersion cooling practical. By removing the constraints of wired architectures, Dukosi enables engineers to deliver safer, more reliable, and higher-performing batteries that are tailored for the demands of tomorrow’s EVs.

- https://www.sciencedirect.com/science/article/pii/S0378775322001185 ↩︎

- https://spectrum.ieee.org/data-center-liquid-cooling ↩︎

- https://assets.kpmg.com/content/dam/kpmg/ie/pdf/2024/12/ie-liquid-cooling-data-centre-design-3.pdf ↩︎

- https://www.ricardo.com/en/news-and-insights/industry-insights/cool-runnings-immersion-cooled-battery-technology ↩︎

- https://www.ricardo.com/en/projects/immersion-cooled-battery-technology-for-electric-vehicles ↩︎

- https://www.dukosi.com/dukosi-cell-monitoring-system-dkcms ↩︎

- https://www.dukosi.com/blog/what-is-dukosi-csynq ↩︎

All original content, graphics and images are copyright of Dukosi.