Accelerate Next-Generation Battery Designs with DKCMS™

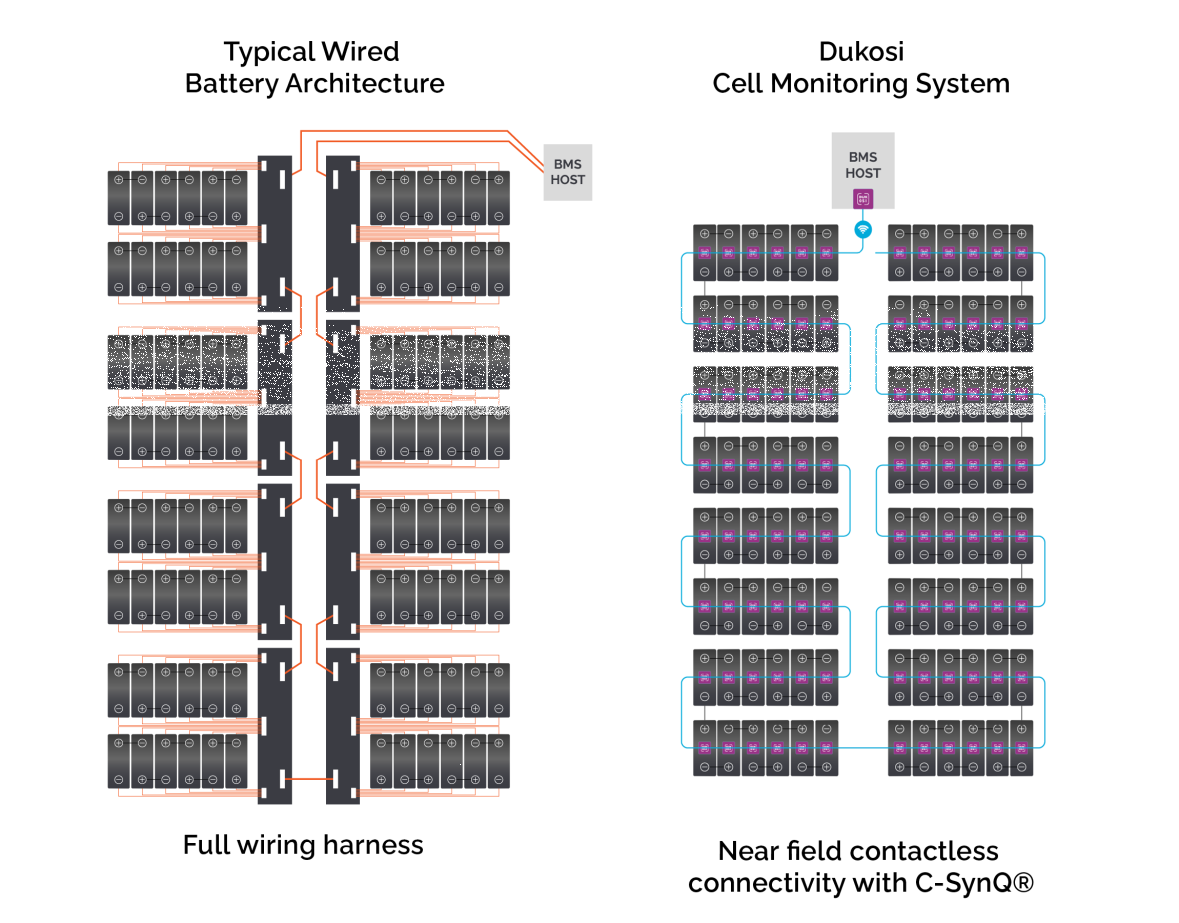

Whether designing a new battery using cylindrical, pouch, or prismatic cells, Dukosi Cell Monitors can be applied to every cell or parallel cell group, whether C2C, C2P, or traditional cell modules, offering unparalleled flexibility and scalability. They also simplify battery architecture by eliminating complex wiring harnesses, thereby reducing design, validation, and manufacturing costs.

Learn more about the core components of the Dukosi Cell Monitoring System (DKCMS™)1 and the advantages it offers to various markets, such as electric vehicles2 (xEV), industrial transportation3, and battery energy storage systems (BESS)4.

Cell Type and Chemistry

The Dukosi Cell Monitors support prismatic, pouch and cylindrical cell types. They are typically installed one per PCB (prismatic or pouch) or per cell group (cylindrical), across a single PCB, and can support any cell chemistry between 1.5-5V, including common NMC, LFP, and their variations, and even emerging alternatives such as sodium-based chemistries.

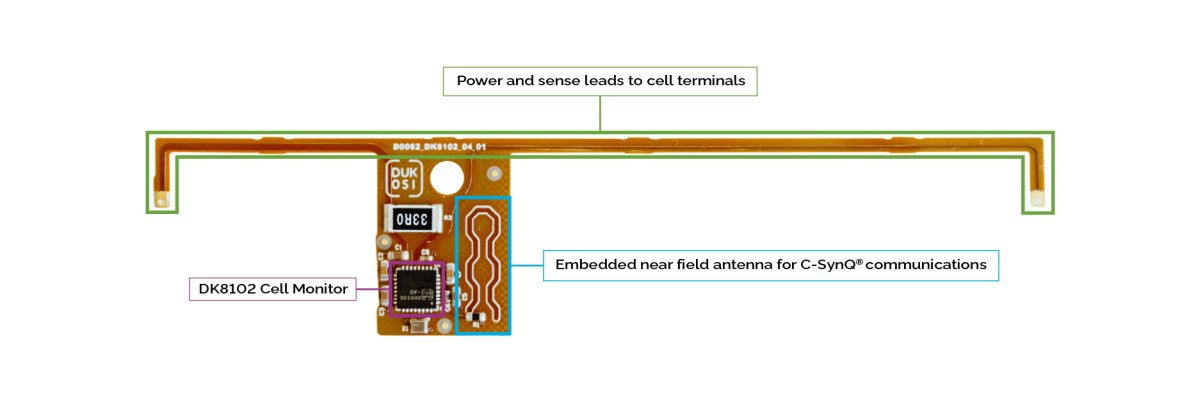

As an all-in-one chip that includes processing, storage, and RF, the Dukosi Cell Monitor is typically installed on a highly compact flexible or rigid PCB between the cell terminals, where the wiring length is optimized to capture the most accurate voltage readings. When stacked together inside the module or battery, their uniformity of install enables easy alignment of each integrated near field antenna, allowing the bus antenna wire to overlap in a straightforward manner and thereby streamlining battery design.

An example of the simplicity of a Dukosi Cell Monitor integration for a prismatic or pouch cell

Prismatic Cells

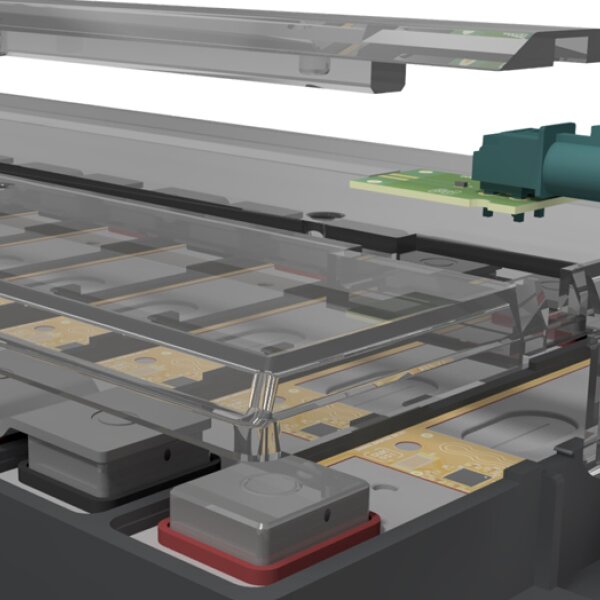

Prismatic cells offer high energy density, space utilization, durability, thermal management, and inherent package strength. By placing the Dukosi Cell Monitor on a highly compact flexible or rigid PCB between the terminals, the chip’s on-die sensor can readily assess the skin temperature of the cell. Up to two additional thermistors can also be attached to each Cell Monitor to capture additional temperature data-points. This is particularly useful to support the increasing size and power-density of large format cells used in battery energy storage systems (BESS), as they retain heat internally for longer, and their surface areas may heat unevenly.

With the cells stacked together and Cell Monitors aligned, the contactless bus antenna can be easily routed near each Cell Monitor, keeping the battery design simple.

An example of a module using uniformly installed Dukosi Cell Monitors on prismatic cells, and a lid-integrated communications antenna, which can streamline battery design and manufacturing efficiency

Pouch Cells

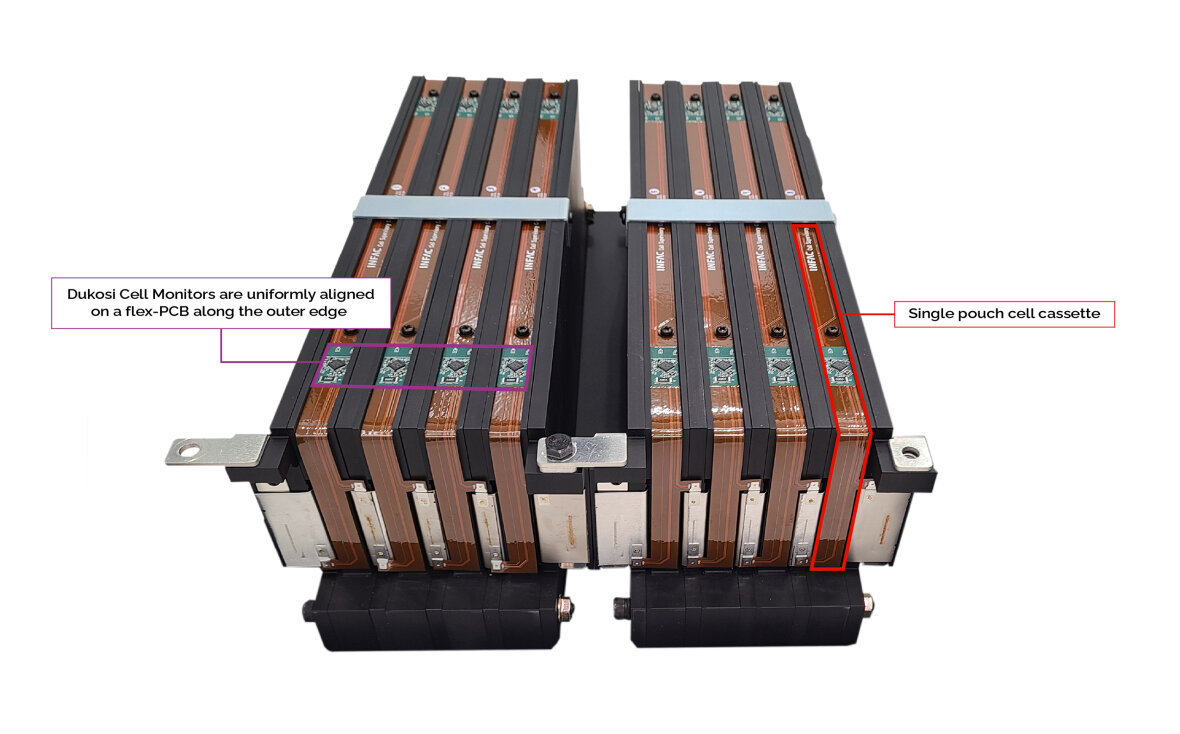

Pouch cells offer high energy density with lightweight construction, and are either used directly or packaged in plastic cassettes to improve durability and ease of installation. Similar to prismatic cells, the Dukosi Cell Monitor is typically placed between the cell terminals, with the PCB antenna accessible to address the near field network cable. Various antenna orientations like in-line or orthogonal can be applied to connect each Cell Monitor to the near field network via bus antenna cable.

A commercial pouch cell design example using DKCMS

As the cells are often elongated, additional thermistors can potentially be integrated into the same PCB line to sample additional temperature points along its length; this is ideal for accurate thermal tracking due to the slimness of the laminated film packaging, which reduces the distance between the internal cell chemistry and the external thermistor(s).

Cylindrical Cells

Cylindrical cells remain popular due to their well-established manufacturing efficiency and yield, mechanical robustness, and thermal management. Dukosi supports all cell sizes, including the increasing trend towards larger formats, like 4680.

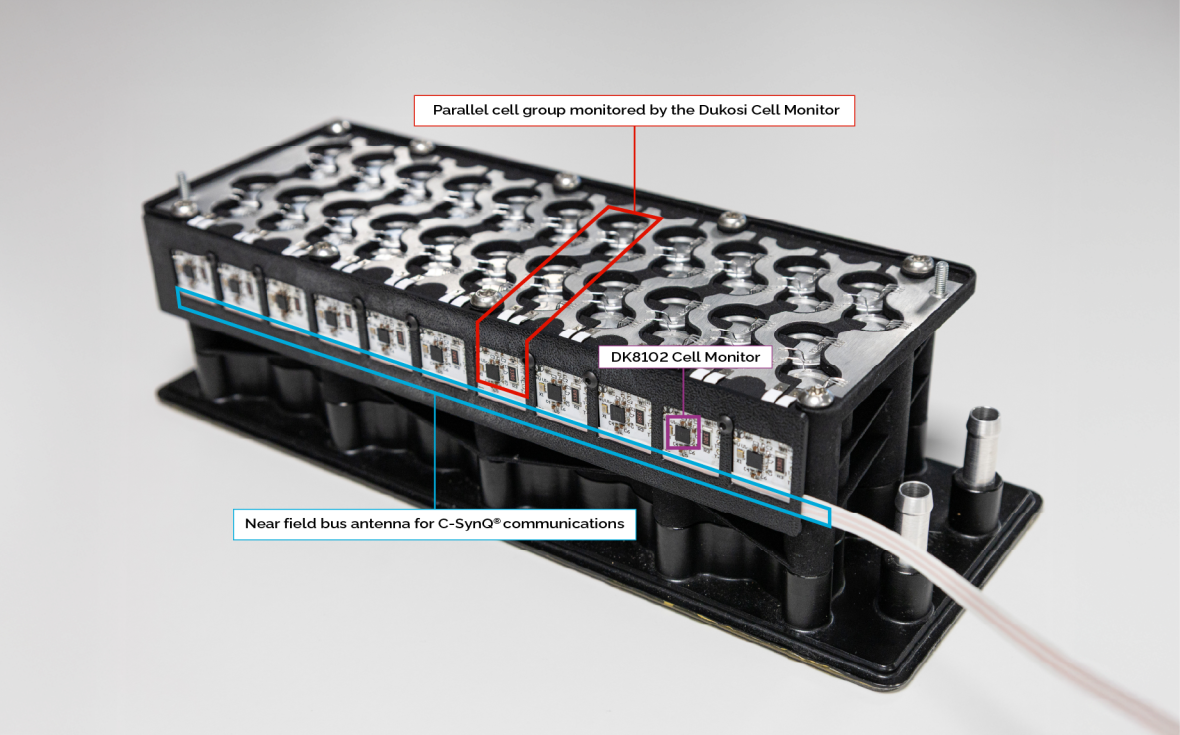

An example of a module using 4680 cylindrical cells and lid-integrated communications antenna

An example of a module using 2170 cylindrical cells and side-mounted communications antenna

Due to their shape and size, cylindrical cells are typically grouped in parallel strings, with one Cell Monitor per string. The Dukosi solution offers benefits such as simplifying the battery architecture and communication with the BMS host, and it has the ability to measure both the core and edge temperatures of the group of parallel cells. Additional thermistors can be attached to each Cell Monitor to provide coverage to all cells.

Extensibility

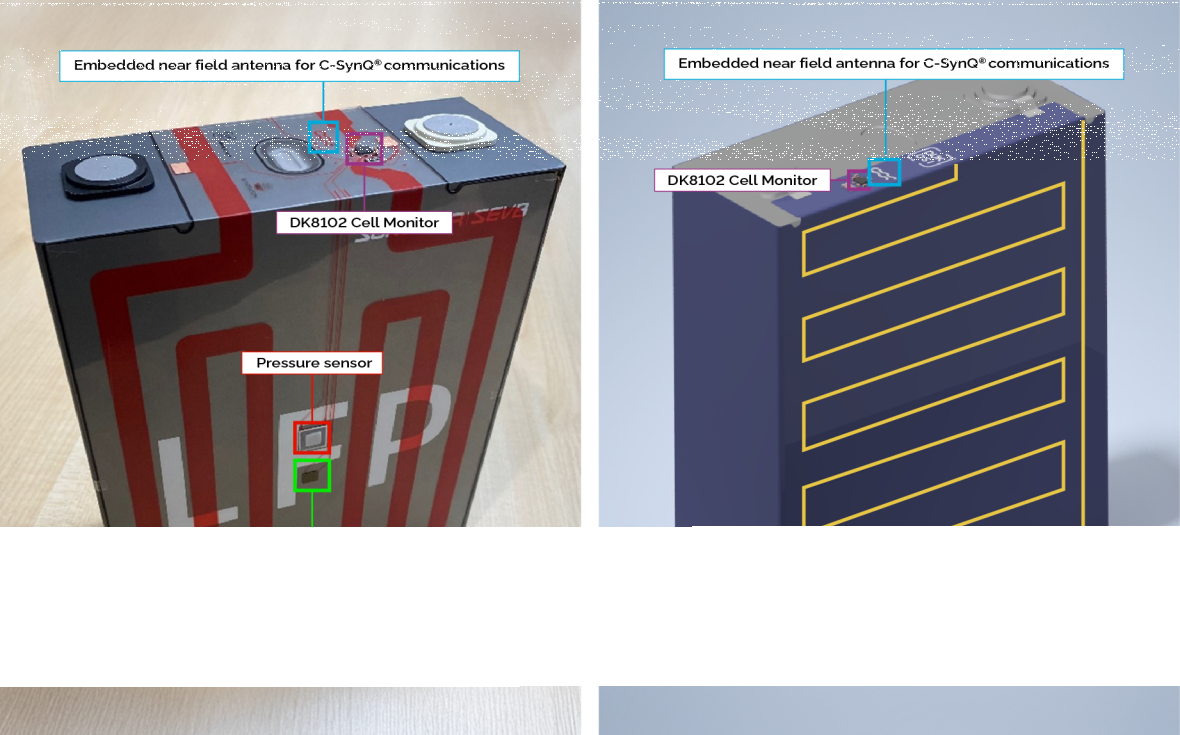

DKCMS is inherently flexible, and the Dukosi Cell Monitors are extensible with additional sensors that can be mounted on or around the cell to provide additional functionality. These can include, but are not limited to, sensors for pressure, gas, light, temperature management (heating or cooling), GNSS (asset tracking), or other GPIO-attached devices.

Example of large format prismatic cells with additional functionality connected directly to, and controlled by the Dukosi Cell Monitor

Easily Migrate from Wired Battery Designs

For traditional battery designs based on cell modules, conventional multi-cell monitor PCBAs and all the internal communications wiring can be removed and replaced with uniformly installed Cell Monitors on each cell. By eliminating the wiring harness within each module, and between the module and the BMS host, battery construction is simplified. The near field bus antenna can be quickly routed once all modules are inserted into the battery housing, or it can be pre-installed into the lid of the casing, potentially even automating this labor-intensive step. This results in significant time and cost savings, while also improving quality control compared to typical wiring harnesses that rely on numerous physical connectors.

DKCMS is even more appropriate for battery’s embracing a new generation of Cell to Pack (CTP), Cell to Body (CTB) or Cell to Chassis (CTC) designs, as the bus antenna can be designed into the chassis directly, saving space, and streamlining manufacturing.

- https://www.dukosi.com/dukosi-cell-monitoring-system-dkcms ↩︎

- https://www.dukosi.com/electric-vehicles ↩︎

- https://www.dukosi.com/industrial-transportation ↩︎

- https://www.dukosi.com/battery-energy-storage-systems ↩︎

All original content, graphics, images and media are copyright of Dukosi.