Building a Wireless Battery Monitoring Solution Truly Without Wires

What is a BMS?

Designing a high-power battery requires not only an effective Battery Management System (BMS) but also the optimization of the entire internal battery architecture.

The BMS host performs calculations to estimate the State of Charge (SoC) and State of Health (SoH)1, as these values are inferred from data captured from the battery’s cells. The cell count can number in the hundreds for applications such as battery energy storage or electric vehicles, so there’s a lot of information that needs to be constantly fed from cells to BMS host processor.

The cells contain an active chemistry of materials that change based on usage patterns, duration of use, and the external environment to which they are exposed. Factors such as temperature, voltage, and current flow significantly affect their ability to receive, retain, and discharge energy. The consequences of improper usage are well understood: ranging in severity with best case being the battery operates inefficiently and fails prematurely; to worst being it experiences thermal runaway, which can result in a self-sustaining fire. Accurate, real-time cell monitoring is therefore absolutely crucial to ensuring the safe and reliable operation of a battery pack.

Most high-power batteries house cells within modules, and then connect groups of modules to the BMS host processor that controls the whole battery. Despite its widespread adoption due to its legacy use, wired architectures are complex and have limitations such as long-term robustness of the many physical connectors, so there are ongoing efforts to replace portions of the wired design with wireless connectivity.

Types of Wireless Battery Management Systems (wBMS)2

Several companies have constructed wireless BMS (wBMS) architectures, which replace some of the wires and connects the cell modules and the BMS host via a far field wireless network. However, wires still connect all the cells within the modules, effectively making these designs semi-wireless. While far field wBMS designs reduce some of the wiring complexity, they often utilize an equally complex wireless system which introduce new challenges such as signal reflections and blockages, mitigating EMI from high-voltage cabling, and ensuring consistent and reliable data packet latency under all conditions.

Using Near Field Wireless

Dukosi has taken another approach – instead of far field wireless, it uses near field wireless communications to connect every cell to the BMS host directly. While sounding similar to NFC – near field communications, it is not. Dukosi’s near field wireless is a proprietary ‘contactless’ approach that creates a star network of cell monitors, blending the advantages of both wired and wireless connectivity.

Dukosi C-SynQ®

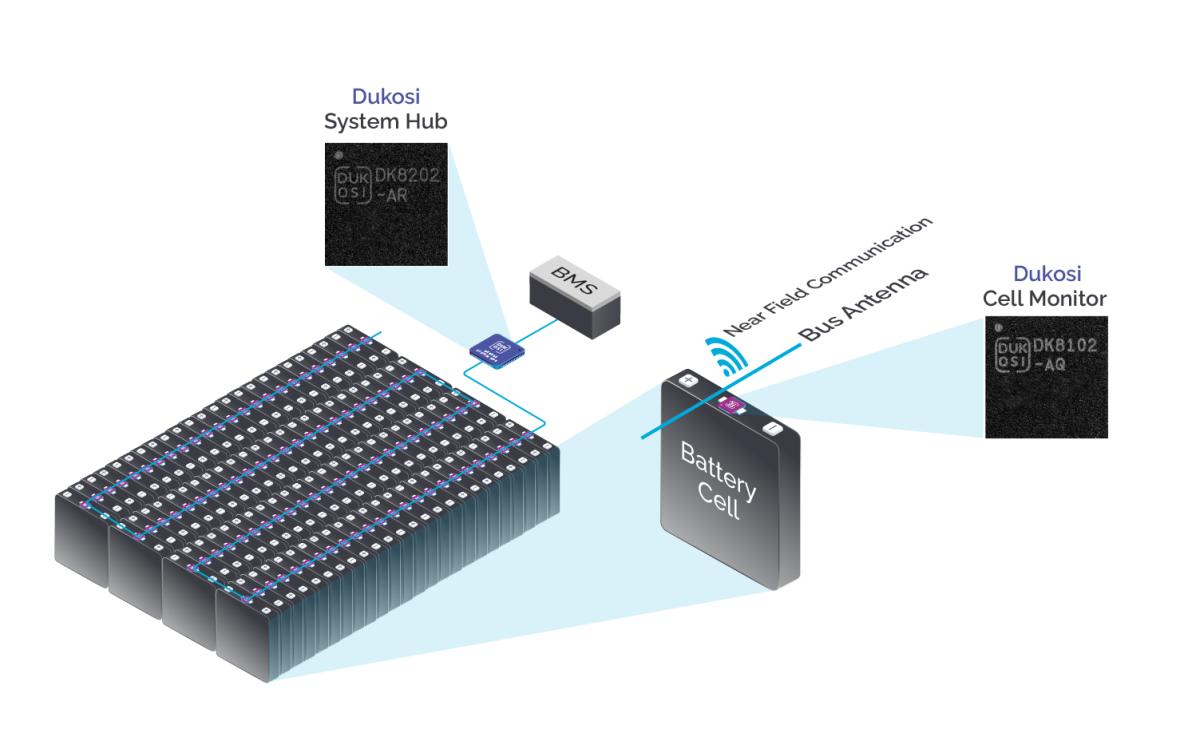

Near field wireless networking is only part of the equation, however. When used in partnership with Dukosi’s proprietary C-SynQ® communication protocol, the Dukosi Cell Monitors synchronously capture and transmit data to a Dukosi System Hub via a secure contactless network using near field wireless communication to a single bus antenna routed throughout the battery pack to the Dukosi System Hub. These four components – Cell Monitors, System Hub, near field wireless and C-SynQ are the key differentiators of the Dukosi Cell Monitoring System (DKCMS) to other wireless solutions.

Dukosi Cell Monitoring System (DKCMS)

Unlike most far field wireless architectures that modify existing wired designs with wireless parts, the Dukosi Cell Monitoring System (DKCMS)3 has been designed from the ground up for high-power batteries, and improves on safety4, reliability, performance, and sustainability5 compared to existing architectures.

Dukosi’s contactless architecture enables flexibility, simplifying battery design and allowing precise routing of the bus antenna through the locations of each cell monitor, even if they are not uniformly distributed. In addition, unlike most wBMS architectures that use separate chips for monitoring and communications, each Dukosi Cell Monitor is a single-chip solution with built-in RF functionality, reducing the need for components such as complex multichannel AFEs and PMICs.

Near field wireless advantages

The combination of near field communication and Dukosi’s proprietary C-SynQ provides the following benefits:

- Robustness: Tolerant to interference, free of typical wire failure points, and inherently isolated from high-voltage wiring.

- Synchronous communication: Cell measurements are captured synchronously and sent with deterministic latency, supported by proven reliability mechanisms that ensure data delivery.

- Wired-like security: Short-range wireless signals remain confined within the battery enclosure, limiting network access to known devices and leveraging a proprietary protocol for communication.

- Scalability: The system supports pack capacity adjustments in per-cell increments for up to 216 cells, with flexible communication for virtually any layout to suit the application.

- Compliance: Automotive and industrial subsystem EMC certification is achieved.

In conclusion, Dukosi’s innovative solution for batteries delivers significant gains in reliability, flexibility, scalability, safety, and total system cost. Learn more about DKCMS.

- https://www.dukosi.com/blog/battery-state-of-health-soh-the-powerhouse-behind-the-battery-passport ↩︎

- https://www.dukosi.com/blog/white-paper-wired-wireless-and-contactless-comparing-bms-design-approaches ↩︎

- https://www.dukosi.com/dukosi-cell-monitoring-system-dkcms ↩︎

- https://www.dukosi.com/blog/monitoring-the-temperature-of-every-cell-to-maximize-safety-and-performance-of-high-power-batteries ↩︎

- https://www.dukosi.com/blog/reducing-the-barriers-to-second-life-battery-cell-use-promoting-a-sustainable-future ↩︎